What are the main application scenarios of CHINESE TYPE U-Joint?

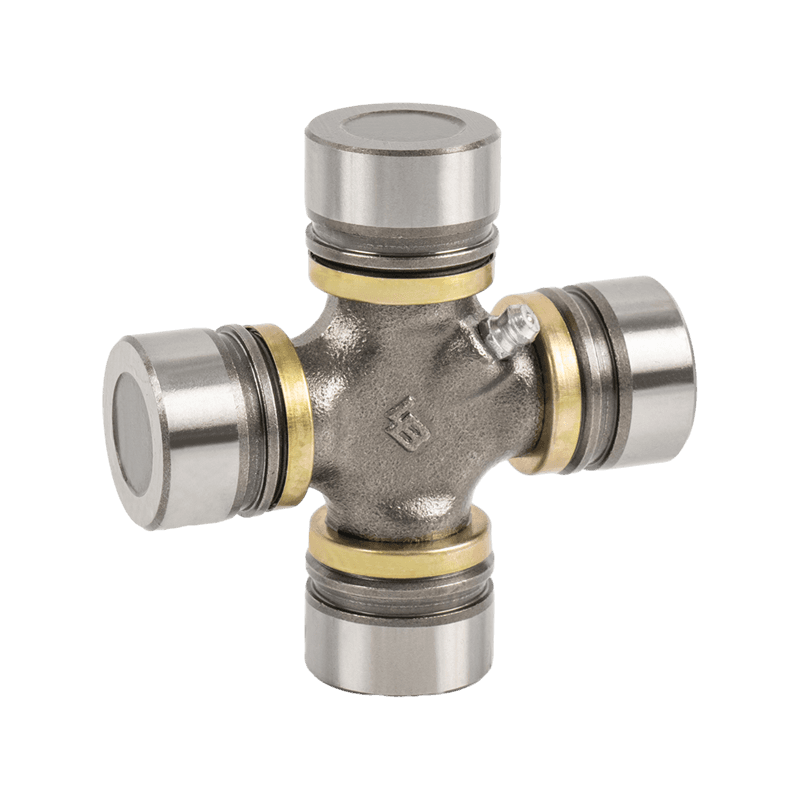

As a key mechanical transmission element, Chinese Type U-Joint plays an important role in multiple industrial fields and mechanical equipment. Its design and function enable it to effectively connect and transmit power, and have good angle compensation capabilities, thereby ensuring the stable operation and efficient operation of the equipment under various complex working conditions.

Chinese Type U-Joint plays an important role in the transmission system of automobiles and commercial vehicles. These vehicles usually require efficient power transmission and flexible angle adjustment capabilities to ensure effective connection between the drive wheel and the drive shaft. The Chinese Type U-Joint is able to undertake this task through its structural design. It consists of two cross-bits, each of which is equipped with bearings at the end, which can move freely when turning, allowing the drive shaft to rotate at different angles and transmit power. This design not only ensures the stability of the vehicle when turning and driving in a straight line, but also provides good driving feel and operating performance.

In agricultural operations, equipment such as tractors and harvesters often need to work in different terrains and working conditions. Chinese universal joints are used to connect engines and power output shafts to support farming, harvesting and other operations of agricultural equipment. These equipment often face the challenges of high loads and long-term operation, so the durability and stability of universal joints are particularly important. The use of ordinary round bearings enables these universal joints to withstand high torque and frequent operation, maintain long-term stable working conditions, and reduce the frequency of maintenance and replacement, reducing the operating costs of farmers.

In the field of construction and engineering machinery, heavy engineering machinery such as excavators and bulldozers usually need to operate in various complex and harsh construction site environments, which requires the equipment to be able to flexibly adapt to different working angles and needs. Through its design advantages, Chinese universal joints can ensure the stable operation of the equipment's transmission system and make angle adjustments when necessary to meet the requirements of various engineering construction. Its simple and reliable structural design enables these universal joints to perform well under high load and high-intensity working conditions, providing important power transmission guarantees for engineering construction.

In addition, the field of industrial equipment is also an important application field of Chinese universal joints. Various types of industrial equipment, such as conveyors, rotary machines, paper machines, etc., usually require power transmission and angle adjustment during the production process. Chinese universal joints have become the core components of these devices through their good adaptability and reliability. They can connect different components and maintain stability and high efficiency during the operation of the equipment, thus ensuring the smooth progress of industrial production. In these devices, universal joints carry important rotation and transmission functions, which have a direct impact on production efficiency and product quality.

As the main tool for marine transportation and work, the propulsion system of ships needs to be able to operate stably in different marine environments and navigation conditions. Chinese universal joints are used in the transmission system of ship main engines and propulsion devices to ensure propulsion efficiency and navigation safety. These universal joints can maintain the stability of the transmission system under the influence of waves and wind, and provide reliable power transmission support for ships.

Wind turbines need to convert wind power rotation into electrical energy, and this conversion process requires efficient power transmission and a stable rotation mechanism. Chinese universal joints are used in the transmission system of wind turbines to ensure stable connection between the rotor and the generator and the ability to transmit high torque. These universal joints can operate for a long time in harsh wind energy environments, and can quickly adapt to changes in wind direction and wind speed to ensure the continuity and efficiency of wind power generation.